...a large amount of stocks in our wharehouses.

...one of the main specialist European braking trademark.

...very hight quality brake parts.

Check out our products and click to see them.

Due to its professional background, a wide-ranging succession of products is put a professionals' disposal as well as an excellent balance among availability, industrial capacity and quality meeting this producing both small series and large volumes per reference in a completely integrated production system ensuring a uniform and top-quality production. The fact that Woking belongs to Eurofren Systems makes it possible since this group owns ten factories all over the world and heads the friction materials production leadership of Aftermarket industry.

The large amount of stocks and the automatic warehouses of our logistical department offer a really short waiting time since the customer's order is placed until it is delivered, in order to face up to an increasing demand. This is one of the keys of aftermarket industry's success.

Our goal is leading Woking to a prestigious trademark sector aimed at professional and selective customers demanding not only security and a top-quality service, but also a guarantee trademark.

- All our efforts are guided to implement a Quality system which is based in two strategies: “Prevention” and “continuous improvement” both are supported in four mainstay:

1. Professional team: Out goal is to maintain and improve the quality of all our products and processes.

2. Product continuous improvement, Innovating to design new friction materials with a homogeneous, tested and controlled production.

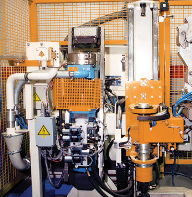

3. Production process improvement, With state of the art technologies, a safe process for the workers, environmentally friendly, reducing the polluting release and raw material and energy consumption.

4. Improve our customer satisfaction, a reactive attitude in regarding their needs, and proactive, offering new solutions and assimilating them in our management system.

- OES-like product performance.

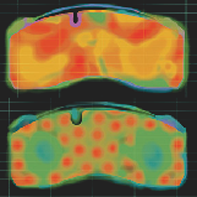

- OE Equivalent quality control tests.

- ECR-90, KBA and AAMVA (USA) approved.

- Continuous evolution in R&D Technological forefront.

- Ecologic material free of heavy metals.

- Woking is Europe's leading Aftermarket friction manufacturer.

- The most flexible and adaptable vertical production to satisfy the specific needs of every customer.

- One mission: To produce 400.000 parts per day with the quality standards you require and deserve.

- Flash moulding allowing a low minimum manufacturing batch 0f 24 brake pad sets.

- Positive moulding presses for high volume production.

- Full vertical integration. In house backing plates, accessories, finishing and packaging operations.

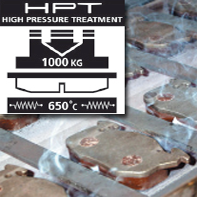

- Involves extreme heat and pressure to scorch the pad surface 1 to 2mm deep, which increases bedding-ability.

- Means safety because it avoids crystallization.

- Is healthy for the environment.

- Our R&D Department runs more than 2,000.000 million km of test per year, checking and researching both the production and the development of new materials.

- We substantially invest in developing our technology and products, to ensure that your safety is guaranteed.

- Full integrated product design: Raw material, components and tools.

- OE matching quality product design. Full accessories, chamfers and slots.

- 6 months maximum launch time from OE sample to release.

- We have a very special mission: To deliver all orders in record time and 100% complete. This facility is able to stock more than 3.5 million sets.

- Our products are distributed worldwide from one state of the arte logistic center located in Spain.

At Woking we position our products at the level they deserve and we focus in providing our customers with all the necessary support and information required such as: catalogues, merchandising, exhibitions, motorshows,....

Please don't hesitate to contact us for more information about work